Flexural Response of Concrete Structures

| ✅ Paper Type: Free Essay | ✅ Subject: Construction |

| ✅ Wordcount: 4190 words | ✅ Published: 26 Jul 2018 |

Literature Review

Introduction

This chapter provides a literature review on the previous studies that have been conducted on the flexural response of FRP/FRC structures. Previous studies related to the effect of using discrete fibers on the concrete properties are first presented with a focus on the use of non-metallic fibers. Later in the chapter, previous studies conducted on continuous FRP-reinforced structures are presented. The chapter ends with a presentation on the research needs and the current research objectives.

Fiber-reinforced concrete

Background

Concrete is known for its superior compressive capabilities. However, it has certain deficiencies like weak tensile strength, low durability, and brittleness. The high demand on more resilient concrete with better durability properties led to the development of fiber-reinforced concrete. Adding discrete fibers to concrete mixtures helps in bridging the micro and macro cracks. The random distribution of fibers resists the propagation of cracks in all directions unlike the longitudinal reinforcing bars that resist in only one direction. Fiber bridging allows stress to be transferred across the cracks, enhancing both flexure and shear resistance. In addition, fiber bridging enhances crack controlling by reducing the crack width and spacing. These enhancements result in better post-cracking ductility and energy absorption capacity.

Fiber types

Fibers are added to concrete mix to restrict the growth of cracks. Several types of fibers are commonly used in concrete construction. These fibers can be metallic like steel fibers, synthetic as polypropylene or natural like jute. The first two types of fibers are the most commonly used in civil engineering applications. Metallic fibers are known for their high ultimate strength, while the alkaline resistance of synthetic fibers makes them suitable for harsh environments. The usage of fibers depends on the required behavior of concrete. A comparison between the physical properties of different fibers is found in table 2-1.

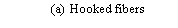

Metallic fibers

Steel fibers are the most common metallic fibers, and the most frequently used fibers in concrete structures. They are known for their high tensile strength, availability and their reasonable cost. Their high strength enhances the post-cracking behaviour of the concrete. This enhancement boosts concrete ability to control cracks and shrinkage. Different shapes and geometries are available to use in market. The typical diameter varies between 0.10 to 1 mm. Steel fibers could be straight, end-hooked, crimped, and flattened-end (Figure 2-1); this versatility helps in fulfilling market needs.

Figure 2- 1: Various steel fibers shapes (Susetyo, 2009)

Synthetic fibers

Recently, the desire to use synthetic fibers, as an additional reinforcement for concrete, has significantly grown. Known for their resistance for alkaline conditions, synthetic fibers became an attractive substitute for steel fibers in concrete applications. In addition, they are chemically inert and have high melting point, which make them appropriate for structures subjected to aggressive environmental attacks. Synthetic fibers, figure 2-2, can be categorized according to their modulus of elasticity. Except for carbon and kelvar fibers, most of the synthetic fibers fall in low modulus of elasticity category, such as polypropylene, polyester and nylon. Synthetic fibers are very flexible, which prevent fibers from sticking or breaking during concrete pumping.

Figure 2- 2: Synthetic fiber (adapted from testilelearner.ca)

Natural fibers

Fibers extracted from animals, such as hair and jute, are the oldest type of fibers used in fiber reinforced concrete. Comparing with their fibers counterparts, they are considered cheap, eco-friendly and available in many countries. With the implementation of new technology, fibers could be extracted from new sources such as basalt rocks. Due to their high resistivity to alkalis and acids, basalt fibers (Figure2-3), made themselves an appropriate candidate for concrete applications. Recent studies conducted by Jianxun Ma et al (2012) and Kizilkanat et al (2015), demonstrated the ability of basalt fibers to enhance the durability and post cracking behavior of concrete.

Figure 2- 3: Basalt fibers (adapted from technobaslat.com)

Table 2-1: Different fibers and their properties

|

Fiber |

Diameter |

Young’s Modulus |

Tensile strength |

|

Type |

mm |

GPa |

MPa |

|

Metallic |

|||

|

Steel |

0.10-1.0 |

180-200 |

700-1800 |

|

Synthetic |

|||

|

Polypropylene |

0.02-1.0 |

5 |

450 |

|

Polyester |

0.01-0.10 |

10-150 |

150-3000 |

|

Kelvar |

0.01-0.03 |

50-70 |

3500-4000 |

|

Natural |

|||

|

Wood |

0.02-0.15 |

10-50 |

300-1000 |

|

Jute |

0.10-0.20 |

25-35 |

250-350 |

Factors affecting the properties of FRC

Fiber volume fraction

The amount of fibers added to a concrete mix is measured as a percentage of the total volume of concrete and fibers. This percentage is called fiber volume fraction (Vf). It generally ranges from 0.5 to 3%. Previous studies showed that the fiber volume fraction is the most influencing parameter on the properties of FRC. It has been shown that increasing the fiber volume fraction enhances the compressive strength, the post-cracking behavior, and the ductility of the concrete element (Jianxun Ma et al., 2012). The increase in the fiber content increases the probability of intersecting the cracks and therefore boosts the ability of concrete to resist cracks. However, higher fiber contents could lead to workability loss and segregation of the concrete constituents. Problems associated with the high fiber content occur as a result of the decreased paste volume fraction available for the free movements of the fibers and aggregates.

Kakooei et al. (2012) investigated the properties of concrete mixes reinforced with polypropylene fibers. The concrete compressive strength, its permeability, and its electric resistivity were evaluated. The fibers were added in amounts that ranged between 0 to 2 kg per cubic meter. It was reported that concrete samples with 1.5 kg per cubic meter of polypropylene fibers showed better results in comparison with other samples. The concrete compressive strength was found to be proportional to the amount of fibers added in the mix.

The study conducted by Jianxun Ma et al (2012) on the influence of basalt fiber content (added in amounts of 1 to 3%) on the physical and mechanical properties of traditional cement-based materials. Fluidity and cube compressive strength tests were carried out. Test results showed that the above-mentioned properties were inversely proportional to the added fiber content. In addition, it was proven that the toughness index was directly proportional to the fiber content up to 2%.

Kizilkanat et al (2015) studied the effect of fiber dosage of basalt and glass fibers on the mechanical properties of FRC. Basalt fiber reinforced concrete (BFRC) specimens showed the highest compressive strength at 0.50% whereas the glass fiber reinforced concrete (GFRC) showed the highest compressive strength at 0.75%. Both mixes showed a reduction in their modulus of elasticity with the increase of the fiber dosage. A40% increase in the splitting tensile strength was observed in the BFRC mix at 1.0%. The increase in the flexure strength was more pronounced in the BFRC mix and was directly proportional to the fiber dosage used. BFRC specimens showed flexural strengths13 and 34% higher than those of the plain concrete specimens at Vf= 0.5 and 1%, respectively. On the other hand, GFRC specimens showed marginal increase in their flexural strengths with Vf= 0.5%. Fiber dosage of 0.25% had no effect on the fracture energy for both types of mixes. However, the fracture energy increased by 50% at Vf=1% in both mixtures.

Fiber aspect ratio

Fiber aspect ratio is defined as the ratio of the fiber length to its diameter ( .Previous studies havedemonstrated that the fiber aspect ratio affected the properties of fiber reinforced concrete. High aspect ratios enhance the bond between the fiber and the matrix, which creates a stiff matrix and enhances the bonding between concrete and fibers. Shah and Rangan (1971) stated that the higher the aspect ratio the greater the ability of fibers to transmit stresses through cracks.

.Previous studies havedemonstrated that the fiber aspect ratio affected the properties of fiber reinforced concrete. High aspect ratios enhance the bond between the fiber and the matrix, which creates a stiff matrix and enhances the bonding between concrete and fibers. Shah and Rangan (1971) stated that the higher the aspect ratio the greater the ability of fibers to transmit stresses through cracks.

Iyer et al. (2014) evaluated the 28-day compressive strength and modulus of rupture of basalt fiber reinforced concrete beams. Specimens had different volume fractions and aspect ratios (same diameters but varying lengths). Plain concrete and steel fiber reinforcement specimens were cast as references. It was found that increasing the fiber length and the fiber amount considerably reduced the workability of concrete. The fiber length had an insignificant effect on the modulus of rupture and the compressive strength of concrete when low percentages of fibers were used. For high fiber percentages, the results showed an increase in the modulus of rupture with the increase of the fiber length. The study showed that a major improvement in the compressive strength could be achieved by using 36 mm basalt fibers with Vf = 0.31% but not as high as steel fiber reinforced concrete specimens.

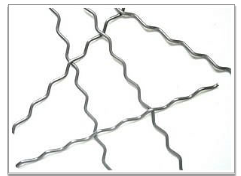

Fiber geometry

Commercially-available fibers have different shapes namely, straight, end-hooked, crimped, and flattened-end (Fig XXX). Recent experimental studies by Susetyo (2009) showed that concrete matrices reinforced with shorter fibers have higher deformation ductility and better crack control over those with long fibers. This was attributed to the large amounts of short fibres that could exist within the matrix, which improves the concrete ability to control cracks and bridge the tensile stresses across the cracks.

Figure 2- 4: Commercially available steel fibers (adapted from steelfiber.org)

A study by Branston et al. (2016) investigated the mechanical properties of two types of basalt fibers (chopped basalt fibers and minibars). It was observed that adding chopped basalt fibers retarded the first crack but had no effect on either the compressive strength or the post cracking behavior. Further examination using scanning electronic microscope showed that the chopped basalt fiber specimens failed due to rupture of the fibers while the minibars-reinforced specimens failed due to fibers’ pullout.

Figure 2- 5 Chopped basalt fibers and Minibars used in Banston’s experiment

Basalt fiber reinforced polymer (BFRP) bar

This section reports on the use of continuous fiber-reinforced polymer (FRP) bars in reinforcing concrete elements. Due to the wide range of FRP types that are commercially available, this section will focus on the recently developed basalt FRP (BFRP) bars and their use as reinforcing bars for concrete sections.

BFRP bars are the newest members in the FRP bars family. They consist of basalt fibers impregnated in polymeric resin. The fibers are extracted from natural basalt rocks through a melting process. They are known for their high tensile strength, high modulus, and large strain to failure. Furthermore, they are known for their better durability and chemical stability over their glass FRP (GFRP) counterparts, which make them adequate for use in alkaline environments. To date, few studies have focused on the use of BFRP bars as internal reinforcement.

The literature presented below is divided to three main sections as follows:

- Literature on the durability of BFRP bars;

- Literature on concrete elements reinforced with BFRP bars; and

- Literature on concrete elements with fiber-reinforced concrete (FRC) reinforced longitudinally with BFRP bars.

Durability of BFRP bars

El Refai et al (2015) investigated the bond performance of BFRP bars to concrete through direct pullout test. Cylinders reinforced with glass fiber reinforced polymer (GFRP) were cast for comparative purposes. Different diameters of BFRP and GFRP bars, with variable embedment length in concrete, were used in this study. Results proved that BFRP bars could be a proper alternative for GFRP bars; as they attained 75% of GFRP bond strength. Smaller diameters of BFRP bars were more adhesive to concrete over the larger bars. This adhesion led to better bond between the concrete and the BFRP bars. It was noticed that BFRP and GFRP bars had similar trend regarding the effect of embedment length on the bond stress; as bond strength of both bars were inversely proportional with the embedment length.

Altalmas et al (2015) studied the effect of various environmental conditions on the bond strength of pullout concrete cubes reinforced with sand-coated BFRP bars. Acid, saline and alkaline solutions were used to simulate different harsh environmental conditions. The program consisted of 62 cube specimens reinforced with either BFRP or GFRP bars. Specimens were either unconditioned or subjected to exposure conditions for 30, 50 and 90 days. Results showed that BFRP specimens had better bond strength with concrete over the ribbed GFRP specimens, regardless the exposure condition,. BFRP specimens subjected for saline and alkaline solutions showed a 25% bond reduction after 90 days, while 14% reduction were reported for those immersed in acidic solution for the same duration of exposure. 25% bond loss was the highest bond reduction reported by GFRP specimens after 90 days. This reduction was reported by the specimens submerged in acidic solution, while 17% reduction was observed for specimens subjected to saline and alkaline conditions.

Elgabbas et al (2015) investigated the short- and long-term properties of three different types of BFRP. The bars were conditioned in alkaline solution simulating the concrete environment to assess their ability as an internal reinforcement for concrete elements. The physical and mechanical properties of the bars were determined according to ACI-440 and CSA-807 test procedures. Concerning the short-term properties, the results showed that BFRP bars met the physical and mechanical requirements stated by ACI and CSA and could be placed in the same category as grade II and grade III GFRP bars. However, the long-term mechanical properties for the alkali-conditioned specimens showed significant degradation. Scanning electronic microscopy (SEM) confirmed that this degradation was attributed to the poor bonding between the resin and the fiber.

Hassan et al. (2016) studied the bond durability of BFRP bars embedded in concrete in aggressive environments. A total of 50 BFRP specimens were immersed in alkaline solution at three different elevated temperatures (40, 50, and 60o C) for 1.5, 3, and 6 months. Five unconditioned specimens were tested at room temperature 28 days after casting for comparative purposes. The bond strength generally increased with the increase in the surrounding temperature. Exposure for 1.5 months increased the bond strengths by 25% and 26% in the specimens conditioned at 50 and 60oC, respectively, whereas a minor reduction in the bond strength (about 4%) was recorded for specimens conditioned at 40. Specimens conditioned for6 months at 40 had the maximal bond loss (about 16%). However, all specimens met the minimum bond strength reported by ACI 440.6 and CSA-S807. Depending on the environmental conditions, the long-term bond-strength-retention predications of the BFRP bars after 50 years of service life ranged from 71% to 92%,

Durability of BFRP bars

Mahroug et al. (2013) studied the flexural response of simple and continuous slabs reinforced with BFRP bars. A total of 6 slabs having different reinforcement ratios and bars arrangement were tested in flexure. One continuously supported slab reinforced with steel bars was also tested as a reference slab. Results showed that slab reinforced with BFRP bars had higher deflections with deeper cracks than the reference slab. Over-reinforced BFRP-reinforced slabs showed higher loading carrying capacity. The authors reported that ACI 440.1R-06 overestimated the flexural capacity in most of BFRP-reinforced concrete slabs. ISIS-M03-07 and CSA-S806-06 reasonably predicted the deflections of the BFRP-reinforced slabs whereas ACI 440-1R-06 underestimated their deflections.

Lapko and UrbanÌski (2014) presented a comparative analysis of experimental and theoretical analysis of concrete beams reinforced with BFRP bars. The research consisted of three beams reinforced with BFRP bars and three reference beams reinforced with conventional steel bars. The results showed that the BFRP-reinforced beams showed higher deflections and crack width in comparison with their steel-reinforced counterparts. CSA806-02 accurately predicted the beam deflections at the initial loading level (up to 20% of critical load) with 9% discrepancy between the theoretical and experimental deflections. As the load increased, the CSA806-02 showed large discrepancy between the theoretical and the experimental deflections (up to 49%). Deflections based on the provision of ISIS (2007) and and by modified equation of Bischoff were the most accurate throughout all phases of loading.

Pawłowskia and Szumigałaa (2015) investigated the flexural behavior of full-scale BFRP-reinforced beams. Three beams with different reinforcement ratios were tested until failure. Results showed that BFRP-reinforced beams having high reinforcement ratios experienced higher ultimate loads and stiffness that those having low reinforcement ratios. However, the former beams showed less ductility than the later ones. It was proven that the flexural design of BFRP-reinforced members is governed by serviceability limits since the ultimate deflections of beams were six times greater than the permissible values. Numerical analysis using ABAQUS showed a good agreement with the experimental results.

Zhang et al. (2015) studied the flexural deflections of concrete beams reinforced with BFRP bars. Six beams reinforced with different ratios in addition to one control steel-reinforced beam were tested under four point loading. Results showed that BFRP-reinforced beams exhibited brittle failure especially the under-reinforced beams. ACI 440.1R-06 accurately predicted the flexure capacities of the beams but underestimated their deflection capacities. A modified equation considering the influence of the increased compressive zone was proposed. This equation showed higher accuracy in predicting the deflections of the BFRP-reinforced beams than the ACI equation. Finite element modeling (FEM) using ABAQUS package was used to model the BFRP-reinforced beams and showed good agreement with the experimental results.

Elgabbas et al (2016) investigated the structure performance of six concrete beams reinforced with BFRP bars. The beams had different reinforcement ratios, number of reinforcement layers, and bar sizes. It was found that the ACI and CSA overestimated the cracking moment by an average of 27% and 24%, respectively. The average bond-dependent coefficient (kb) was estimated at 0.8, which was in agreement with the recommendation of the Canadian Highway Bridge Design Code. The obtained results confirmed that the pre-cracking response of all beams was similar until cracking occurred with no evidence of being affected by the reinforcement ratio. However, after cracking, it was reported that beams with higher reinforcement ratios had better crack distribution and less crack width. The authors concluded that CSA provisions provided reasonable deflection yet conservative values over the ACI for beams reinforced with BFRP.

Tomlinson and Fam (2015) evaluated the flexural and shear performances for concrete beams reinforced with BFRP bars and stirrups. A total of nine specimens were reinforced with BFRP bars were tested under four-point loading. Steel reinforced specimens were cast for comparison purposes. The parameters investigated included the type of stirrups (steel or BFRP) and the reinforcement ratio (varying from 0.28 to 1.60). Results showed that the service and ultimate loads of BFRP specimens were directly proportional to the flexural reinforcement ratio, regardless the shear reinforcement type. In addition, BFRP-reinforced beams showed significantly higher strengths (2.8 times) in comparison with their steel-reinforced counterparts having the same reinforcement ratio. ACI and CSA adequately predicted the flexural strength of the BFRP-reinforced beams.

Ge et al. (2015) studied the flexural behavior of hybrid concrete beams reinforced with BFRP and steel bars. Three hybrid concrete beams reinforced with BFRP bars and steel bars, one concrete beam reinforced with BFRP bars and one concrete beam reinforced with steel bars were cast. Results showed that the ratio between the area of FRP bars to that of steel bars ( ) governed the deflection and the crack spacing properties of the hybrid beams, as both decreased with the increase of this ratio. It was observed that under same loading, the deflection and crack spacing were maximal in the BFRP-reinforced beams and minimal in the steel-reinforced ones. Hybrid beams showed deflections less than those encountered in the BFRP-reinforced beams but higher than those of the steel-reinforced ones. It was also proven that the average crack spacing calculation theory is valid for hybrid-reinforced beams, while a new formula for calculating the flexural capacity was proposed for those beams.

) governed the deflection and the crack spacing properties of the hybrid beams, as both decreased with the increase of this ratio. It was observed that under same loading, the deflection and crack spacing were maximal in the BFRP-reinforced beams and minimal in the steel-reinforced ones. Hybrid beams showed deflections less than those encountered in the BFRP-reinforced beams but higher than those of the steel-reinforced ones. It was also proven that the average crack spacing calculation theory is valid for hybrid-reinforced beams, while a new formula for calculating the flexural capacity was proposed for those beams.

Hybrid FRC/FRP specimens

Won et al (2010) investigated the flexural cracks of 16 beams reinforced with FRP bars. Parameters used in this study were the reinforcement bars type (GFRP or CFRP) and the reinforcement ratio. Steel reinforced specimens were cast for comparative purposes. 1% by volume of crimped polypropylene fibers was added to the concrete mix. Results showed that adding polypropylene fibers enhanced the cracking response of the concrete. However, it reduced its compressive strength by 23%, in comparison with the plain concrete. Both GFRP and CFRP under-reinforced FRC beams had smaller cracks, while the over-reinforced ones had an increased number of cracks formed. Polypropylene fibers didn’t have much of an effect on steel reinforced specimens; as beams with plain concrete and with FRC had similar cracking response.

A total of 36 specimens were fabricated by Belrabi et al. (2011) to investigate the effect of environmental exposure on the long-term bond behavior of FRP/FRC structures. Specimens were subjected to combined freez eand thaw cycles and high temperature while being submerged in salt solution. FRP bars in plain concrete were subjected to the same environmental conditions for comparative purposes. It was found that 0.5% of polypropylene fibers significantly enhanced the bond durability. An average of 28% reduction in bond strength was observed for FRP bars in plain concrete whereas only 6% reduction was observed for FRC specimens. Furthermore, 26% average reduction in design bond strength was reported for plain concrete specimens while only 10% reduction was reported for FRC specimens.

Wang and Belarbi (2013) investigated the long-term flexural performance of FRP/FRC beams. Beams cast with plain concrete served as controls. Twenty-six over-reinforced concrete beams were subjected to freeze and thaw cycles followed by high temperature cycles before being tested in flexure. It was reported that all specimens failed due to concrete crushing. Results showed that conditioning had slight effect on the flexural capacities of both plain and FRC beams. However, 0.5% of polypropylene fibers enhanced the ductility index of both conditioned and unconditioned specimens by an average of 30%.

Wang and Belrab (2015) conducted a research to investigate the possibility of using steel-free system to overcome corrosion problems associated with steel. Their systems consisted of hybrid CFRP/GFRP bars and 0.5% randomly distributed polypropylene fibers. A total of 12 over-reinforced specimens were subjected to four-point loading configuration. The investigated parameters included the size and type of FRP bars and the concrete mix (FRC and plain concrete). All plain concrete specimens failed by concrete crushing. However, FRC beams failed in a more ductile behavior that was attributed to the bridging effect of the added fibers. Results showed that the fibers had significantly enhanced the concrete ultimate stain to an average of 3,300 micro-strains while 2,950 micros-trains were measured in theplain concrete beams. The addition of fibers improved the flexural capacity for the FRC beams up to 9% and the ultimate deflection up to 27%.

High et al. (2015) conducted an experimental program to investigate the use of BFRP bars as flexural reinforcement for concrete members. In addition, they studied the effect of using chopped basalt fibers as an additive to enhance the mechanical properties of concrete. Six one-way slabs reinforced with BFRP bars were tested in flexure and their results were compared with those predicted by ACI 440.1R-06.Under-reinforced slabs showed a lower carrying capacity than the balanced and over-reinforced slabs due to the rupture of BFRP bars. It was proven that ACI 440.1R-06 adequately predicted the flexure capacities of the slabs but significantly underestimated the deflections at service loads. More precise deflection values were predicted by using the equation proposed by Bischoff and Gross (2011) while neglecting the effect of tension stiffening. The use of chopped basalt fiber resulted in an increase in the modulus of rupture of concrete with a slight effect on the compressive strength.

Conclusions:

A summary of the previous studies that have been carried out on the flexural response of concrete structures reinforced with FRP, FRC or hybrid has been presented. Parameters recognized to have a significant effect on the behaviour of these elements are identified. The previous studies were categorized the reinforcement type; FRC, FRP or hybrid. An overall review on the factors affecting the behaviour of FRC is presented with a focus on non-metallic fibers. In addition, factors making non-metallic fibers more preferable than metallic fibers are highlighted. From the previous literature review, the following points are concluded:

- The presence of fibers in concrete has a great influence on the behavior of concrete structures. They have been successfully known for their ability to control cracks and shrinkage and enhance the post-cracking behavior. Those enhancements occur as a result of the bridge action caused by fibers.

- Fiber volume fraction is the most influencing parameter on the properties of FRC. Sufficient fibers are required to enhance the bridging action, while excessive fibers could lead to workability and segregation issues.

- Synthetic fibers are considered a promising candidate for reinforcing concrete structures. Owing to their alkaline resistivity, high melting point and high tensile strength, they are measured as a promising replacement for steel fibers in reinforcement concrete applications.

- Aspect ratio of the fiber is another important factor which influences the behavior of FRC. It has been reported that compressive strength and concrete toughness are considerably affected by the aspect ratio of fibers used in the concrete mix.

- The type of bars used as flexural reinforcement has a major effect on the behavior of the concrete elements. This occurs due to the variance in the physical and mechanical properties of the materials used in forming the bars.

- Reinforcement ratio is a significant parameter in BFRP concrete structures. It was found that specimens having high reinforcement ratios experienced higher ultimate loads and stiffness.

- ACI 440.1R-06 and CSA S806-06 were accurate in predicting the flexure capacities of BFRP structures however, they underestimated their deflection capacities.

- There is a noticeable lack of studies on the flexural response of BFRP slabs in the presence of basalt mini-bars. Among the few studies, this mentioned hybrid system proved to be efficient in enhancing the compressive strength of the concrete and improving its overall durability.

- None of the previous studies has investigated the effect of different fiber volume ratios of basalt mini-bars on the behavior of concrete structures reinforced with BFRP bars.

- None of the previous studies has developed a numerical model that is capable to simulate the flexural response of BFRP reinforced concrete structures in the presence of different volume fractions of basalt mini-bars.

Research objectives:

The overall objective of the current study is to investigate the flexural response of BFRP slabs reinforced with different volumetric ratios of basalt mini-bars. The detailed procedures of the current study are presented

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal